Cold rolled carbon steel

Cold-rolled carbon steel undergoes forming development at room temperature, giving rise to its recrystallization. It is the most widely used procedure when a finer finish and superior mechanical characteristics are required.

Cold rolling increases the strength and hardness of the steel and decreases its ductility (that is, its ability to deform plastically sustainably without breaking), and for this reason it is necessary to master it in a development called annealing. For this reason, cold rolling is fundamentally hot rolling that has undergone additional forming development.

Description

Cold rolled carbon steel is a form of steel made by rolling carbon steel at temperatures below its recrystallization point. This increases its strength, hardness, and ductility, making it ideal for applications that require additional mechanical strength. Cold rolled carbon steel is also more resistant to corrosion than traditional carbon steel, making it ideal for applications where corrosion resistance is required.

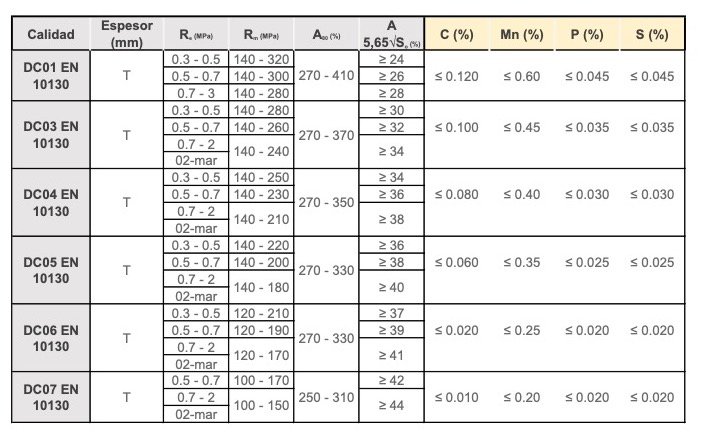

Steels for cold forming and deep drawing

They are a range of cold-rolled non-alloy mild steels, with guaranteed maximum values of yield strength and tensile strength, and guaranteed minimum characteristics of ductility (elongation at break) and good formability.

The incredible formability of these steels makes cold forming operations possible, making them ideal for deep drawing applications.

Cold rolled carbon steel for structures

Structural steels are carbon-manganese steels with a guaranteed minimum strength value (yield strength and tensile strength) and good ductility. We are talking about steels suitable for various situations.

Structural steels are noted for their acceptable weldability in all common welding processes. This class of steels is used primarily in situations where strength properties need to prevail over formability and ductility.

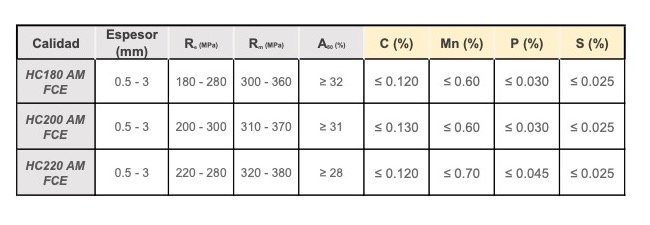

High elastic limit steels

High-strength steels are characterized by a low carbon and micro-alloy content, which gives them outstanding functional characteristics as well as aptitude for welding and coating. The hardening of the material, obtained by means of its dominated internal purity and fine-grained composition, guarantees its incredible mechanical resistance settings.

Characteristics of advanced weldability and good formability are mixed. To these characteristics are added very reduced margins of alteration of the mechanical characteristics, which makes possible their conformation (in presses or in automated lines). In addition, they reach very satisfactory scenarios of resistance to fatigue and shock.

Additional information

| Formato | Coil, Iron, Strip |

|---|