Coated carbon steel

Coated carbon steel is a steel alloy with an oxide layer or metal alloy on the surface to improve corrosion resistance. This protective layer is applied by a chemical or electrochemical process, which helps extend the life of carbon steel. This is an ideal solution for high wear applications that require adequate corrosion resistance.

Therefore, we can say that coated carbon steel are those steel materials that go through another process that provides protection against environmental inclemencies.

Description

Coated carbon steel is a strong and durable material. It is made of carbon steel with a protective coating, which allows it to resist erosion, deterioration and water damage. The main characteristics of coated carbon steel are its resistance to corrosion, its resistance to water damage and its durability.

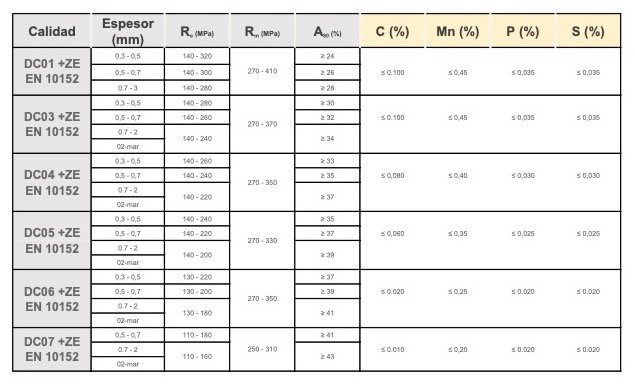

Carbon steel with Electrogalvanized coating:

Electrogalvanized steel is a flat, cold-rolled carbon steel product, coated with a pure zinc film, on one or both sides, in which the uniformity and regularity of the coating thickness stand out.

Offers acceptable corrosion resistance for indoor situations.

It gives extraordinary formability in deep drawing with small spraying and, likewise, incredible weldability, through the uniformity and regularity of the zinc coating.

Electrogalvanized products make up an optimal substrate for paint application, both in terms of adhesion and appearance, a property that is accentuated through the use of post-coating area treatments: phosphating and/or passivation.

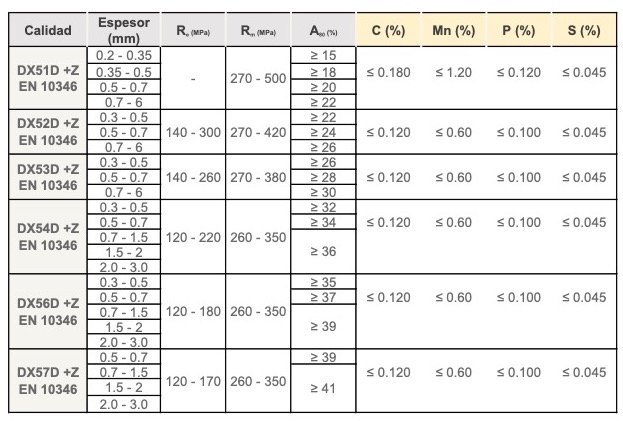

Carbon steel with hot dip galvanized coating

Coated steels formed by a steel substrate on which a zinc coating is applied by means of a continuous development of hot-dip galvanizing. These kinds of materials are available in steel grades ranging from steels for bending and deep drawing applications and structural steels to high yield strength steels.

It is feasible to ensure a shiny surface appearance obtained by means of individual characteristics related to the tempering process. (suppression of skinpass development or skinpass with smooth rolls to achieve reduced roughness)

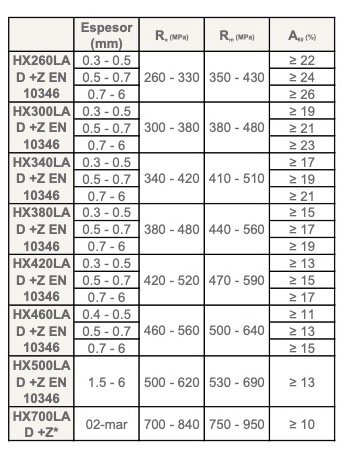

Galfan steels with zinc-aluminum alloy coating.

The galfan steel flat product is coated on both sides with a zinc-aluminum alloy (95% zinc and 5% aluminium), applied by means of continuous hot-dip development.

This class of material is available in a wide selection of steel grades, ranging from cold-forming and deep-drawing process steels, to structural steels and high-yield, low-alloy steels.

The existence of aluminum in the coating gives Galfan steel corrosion resistance characteristics that are clearly superior to those of galvanized steels with a similar thickness level. On the other hand, this material shows superior edge corrosion resistance scenarios.

Alusi steel with Aluminum-Silicon coating

The Alusi flat steel product is coated on both sides with an aluminum-silicon alloy (90% aluminum and 10% silicon), applied by means of continuous hot-dip development. This class of material is available in a wide selection of steel grades, ranging from cold-forming and deep-drawing process steels to structural steels.

Additional information

| Formato | Coil, Iron, Strip |

|---|